Custom Soft Lens Designs

There are two major categories of soft lenses available.

One, is stock parameters where the prescriber has limited parameter, design, and material choices.

The other is “custom” where the prescriber can choose from a wide range of lens designs, powers, zone sizes, thicknesses and diameters. There are other differentiators as well, such as the patient’s diagnosis (irregular astigmatism), diagnostic lenses that are also custom-made, replacement schedule (typically, 3-months), and packaging (usual in a vial, rather than a foil-pack).

There has been a growing trend to use more custom soft lenses, in fact a January 2022 survey noted that 35% of the respondents felt custom soft lenses offered excellent growth potential in their practice for the upcoming year1.

The bulk of soft lenses prescribed employ the “one-size fits all” philosophy which works well with most patients. But, for those that don’t – and it could be as high 20-25% of wearers - custom soft lenses are an excellent alternative to improve the wearability and fitting characteristics.

Here’s 3 top reasons to consider custom soft lenses after attempting stock lens designs.

- Poor centration

The goal of a proper soft lens fit is a well centered lens with an overall diameter 2.5mm-3.00mm larger than the size of the cornea. Thus, a 12.0mm HVID would have a diameter selected of 14.50mm.

Base curve has an impact as well, usually selected to equal the mean keratometric measurement.

The combination of the base curve and lens diameter aids in this centration by the sagittal (SAG) height relationship between a contact lens and a respective cornea.

It’s been noted there is a fairly strong correlation between small diameter corneas contributing to shallower sagittal depths and large diameter corneas contributing to deeper sagittal depths, exceptions for this parameter means it may not be a reliable indicator of sagittal depth2. Thus, calculations of an initial design, followed by a diagnostic fitting with that lens is the most accurate method for determining lens parameters.

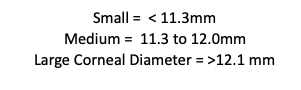

Although HVID can be determined many ways, clinically we refer to them in ranges and categorize them as small, medium or large. Here’s one example of the corneal diameter categories.

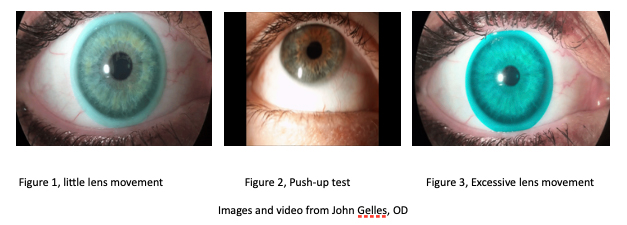

The images below demonstrate a well-centered 14.5mm lens with adequate overlap 360° around the cornea vs a decentered lenses that is too small and should have custom diameter increased to 15.00mm to improve centration.

- Movement

Stock parameter soft lenses usually exhibit only a limited amount of vertical movement during the blink cycle, maybe only .25-.50mm (figure 1). While difficult to notice, it’s often so small that it’s only apparent when using the push-up test (figure 2). No lens movement may result in decreased comfort and wearing time and should avoided if possible.

Custom soft lenses are easier to visualize lens movement due to the design and thicknesses. Typically, we’d expect 0.50-.75mm of movement. Any amount greater than that and we can expect dislocation of the lens, often superiorly (figure 3)

To increase movement, consider decreasing lens size, if possible, then flatten the base curve. To decrease lens movement, increase lens diameter first, then consider steepening the base curve. Note: these lenses have been died with lissamine green to more easily visualize lens movement.

- Decreased comfort and wearing time

Approximately 15-20% of soft lens wearers discontinue lens wear annually. There’s no one reason why, but instead it’s multifaceted with a combination of dryness symptoms, lens awareness, decreased comfort and decreased wearing time.

Custom soft lens designs can be helpful here.- The ability to change lens materials within the same design can aid in decreasing dryness symptoms by switching from a silicone hydrogel to a hydrogel – or vice versa.

- A slightly thicker custom lens won’t dehydrate on the eye resulting in better wetter for longer periods of time.

- A multitude of base curve and diameter combinations can improve fitting characteristics to control lens positioning and movement – thus decreasing lens awareness.

Custom soft lenses can be a great addition to our soft lens fitting toolbox and should be considered when limited parameter stock designs result in an unsuccessful wearer experience.

References

- Jason J. Nichols, OD, MPH, PHD; Lisa Starcher; Contact Lenses 2021; CL Spectrum January, 2022

- Caroline, Kojima; Soft Special Edition, World Wide Vision XII